HSL-PP

HSL-PP

Filling & Closing Machine

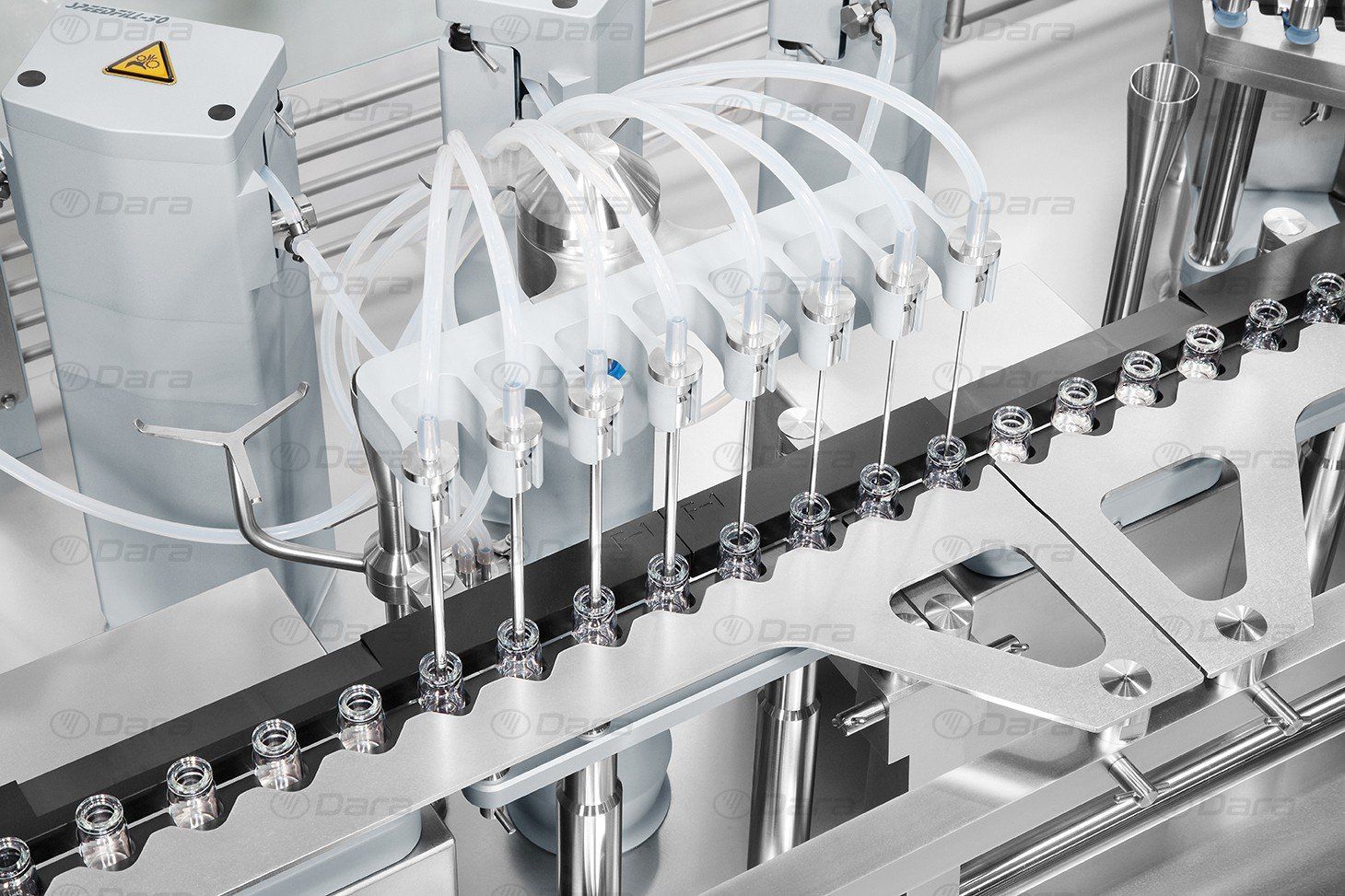

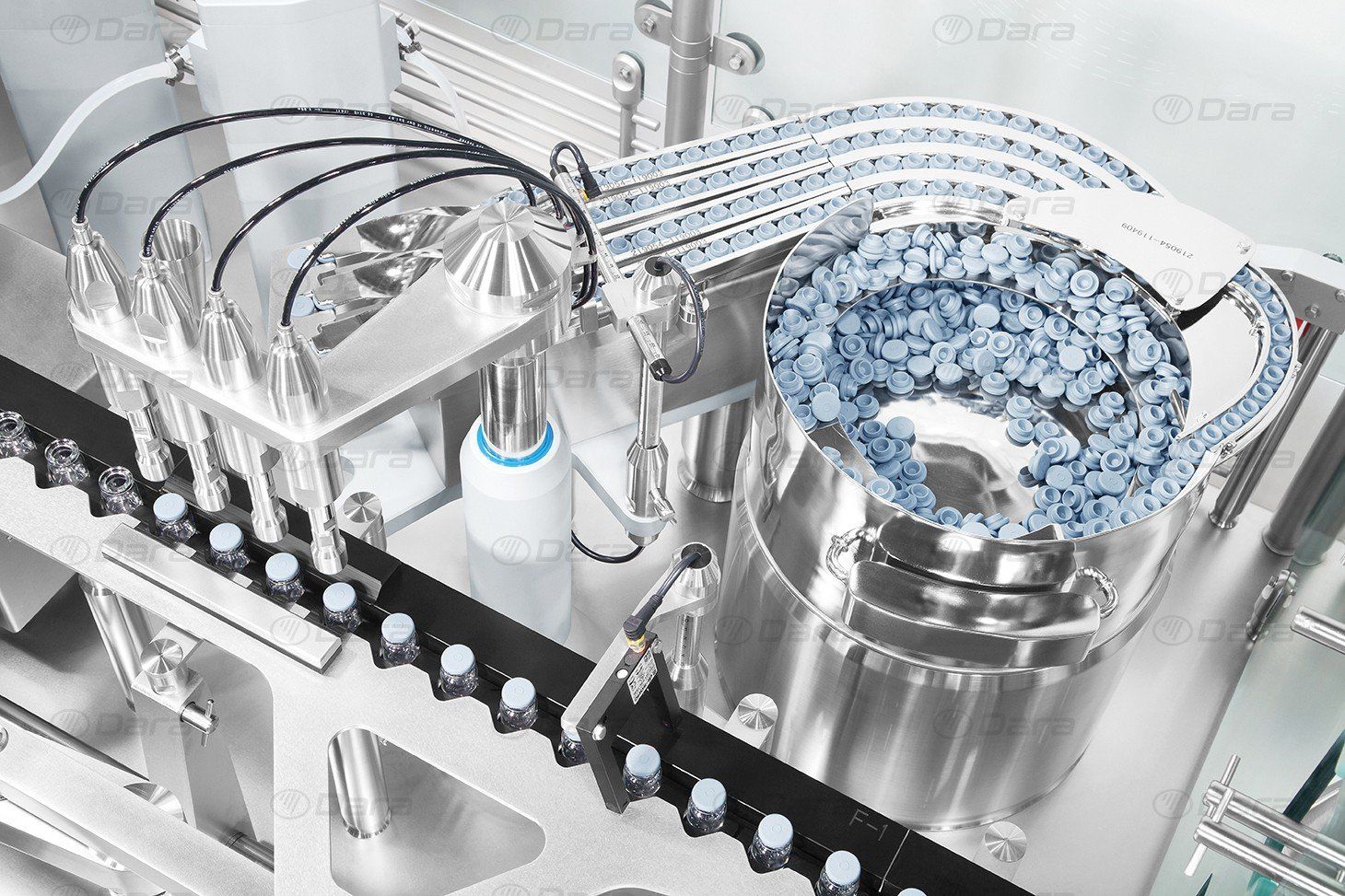

The equipment is for automatic filling, stoppering and capping of vials and bottles in glass, plastic, or metal, for liquid, semisolid, and powder products, in sterile areas or clean rooms.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Main features

- The filling station can be equipped with volumetric, peristaltic, time-pressure, or flow dosing system for liquid, or vacuum-pressure dosing system for powder.

- The pick & place station can place rubber stopper onto the vial fully or partially.

- The closing head can be equipped with three forming rollers or tangential rolling heads, suitable for flip-off or pilfer-proof cap.

- Quick and easy format parts changeover without tools.

Options

- Gravimetric dosing system through scale.

- Vacuum-assisted or gas-flushing before, during, and/or after filling.

- Automatic 100% In-Process Control (IPC).

- Automatic reject station for defective products.

- Aluminum cap printing/codification.

- CIP/SIP compatible dosing system.

- 21 CFR part 11 compliant data acquisition system.

- Barrier system: oRABS, cRABS, or isolator.

WHERE TO FIND US

Jerempli Co., Ltd.

11F, No. 1, Songzhi Rd., Xinyi Dist., Taipei City, TW-110411, Taiwan

CONTACT

Phone: +886287292123E-mail: info@jerempli.com

© 2024

Jerempli Co., Ltd. | All Rights Reserved