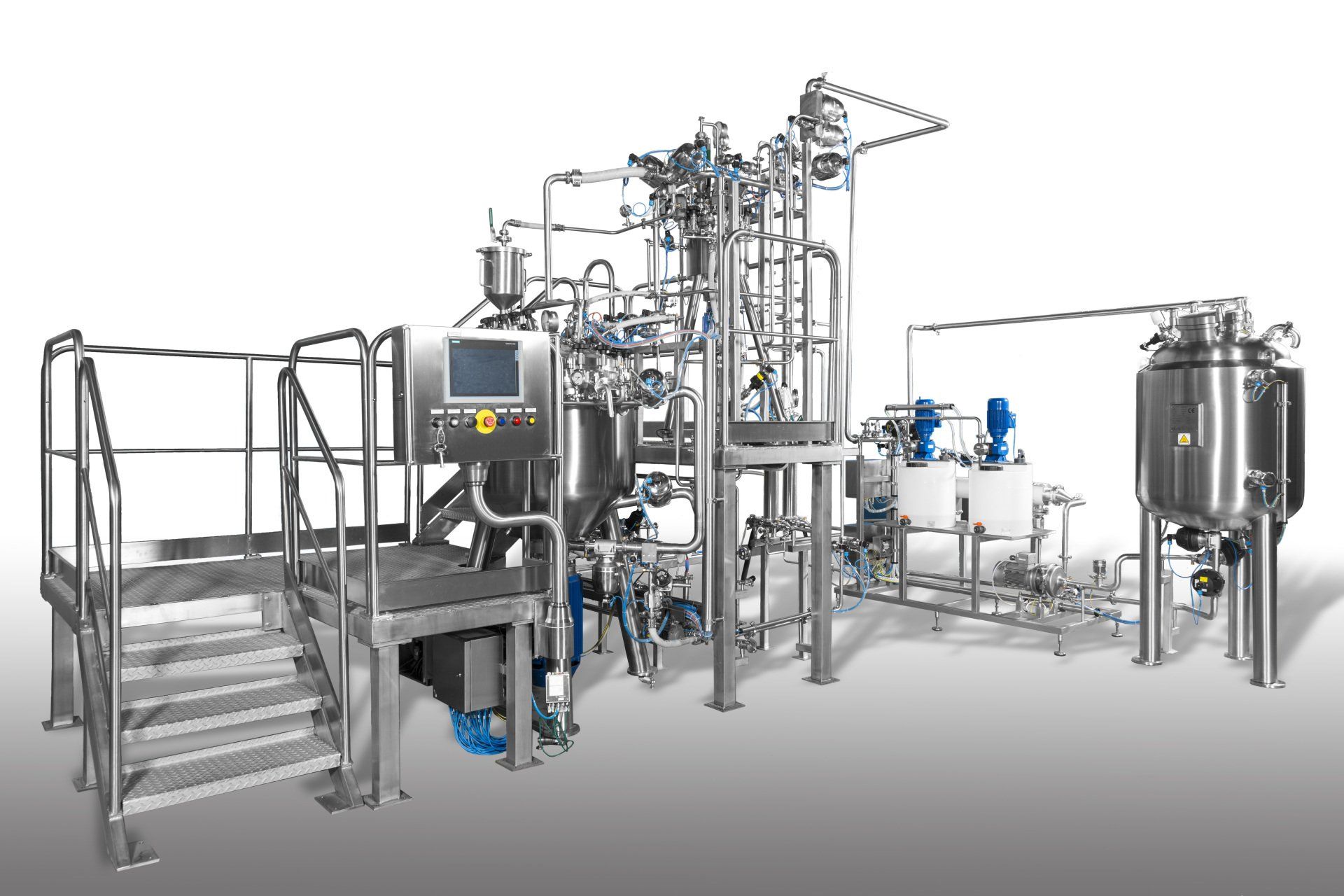

Suspension Plant

Preparation Vessel for Oral/Nasal Product or Suspensions.

Process different types of products granting the utmost working versatility maintaining the lowest possible production costs.

Main features

- High flexibility of the production sequences.

- Use of different technologies for ingredients loading perfectly integrated in the production system.

- CIP design and management to avoid cross contamination.

- Product transfer either by customized transfer panels or by automatic Mix-Proof Valves according to end-users requirements.

- Wide choice of agitation systems granting good performances with multi products preventing risk of ingredients sedimentation.

Options

- Powders blender for large quantities of solids need to be dissolved into a liquid phase.

- Mix-Proof Valves meet the highest demands for hygienic processing of sticky products, products with high content of solids, or applications that require close-to- aseptic conditions.

- Appropriate control systems for automatic/semi-automatic operations in compliance with 21 CFR part 11