MODULINE™

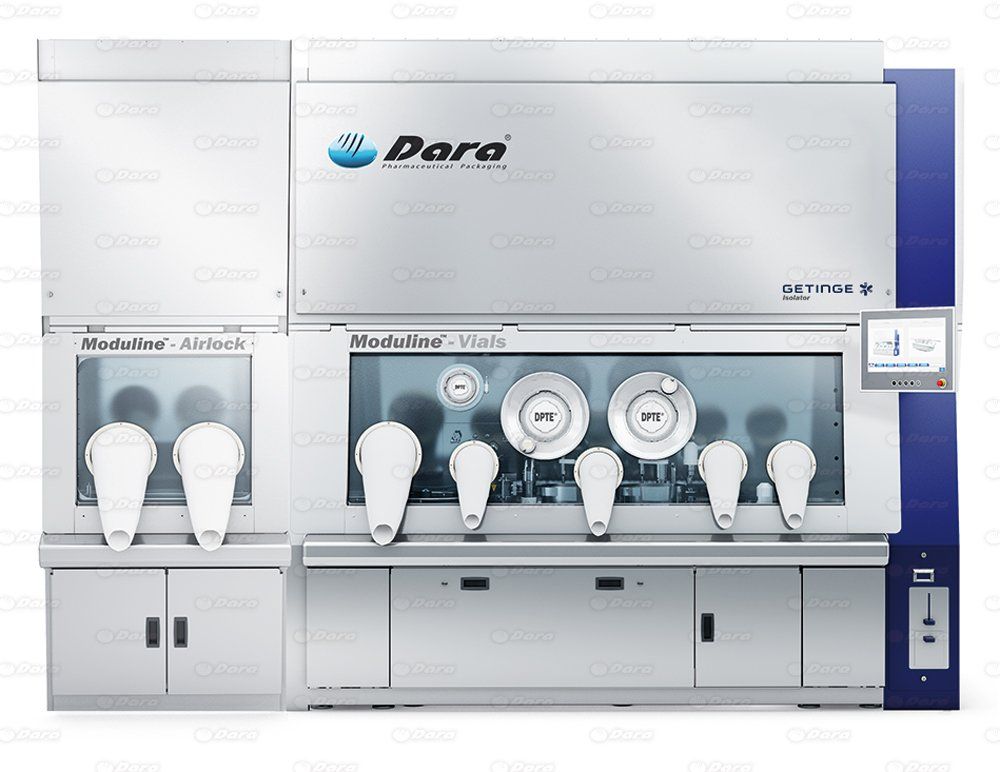

Collaboration of Getinge & Dara Pharma.

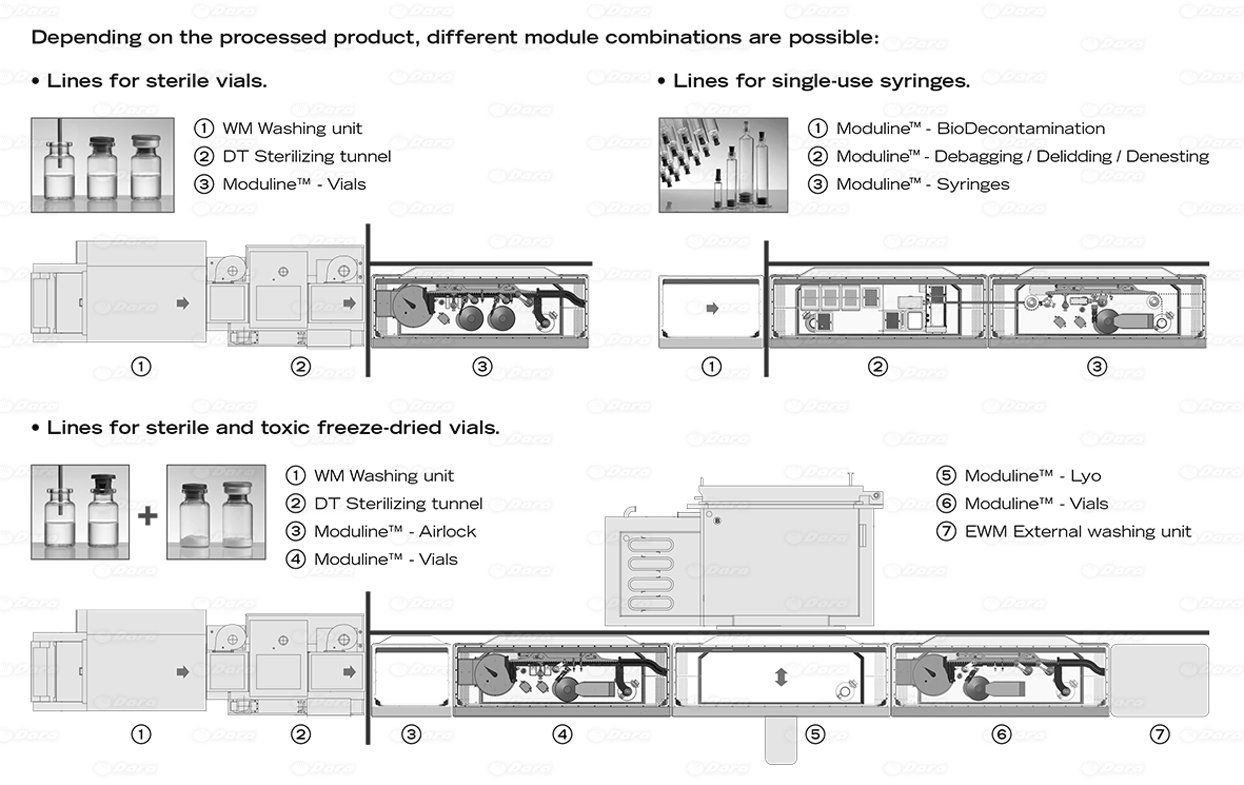

A fully automated filling station is placed inside a standard isolator of a single design, for processing either vials, bottles, syringes or cartridges, for automatic filling of any liquid or powder in sterile conditions.

Main features

- For aseptic and aseptic-toxic products, i.e. operation under positive or negative pressure.

- Compact and modular design.

- Good ergonomics and easy access through one-piece glass window with "automatic" opening and closing.

- Same isolator design to process vials, bottles, syringes and cartridges.

- Suitable for “Ready to Use (RTU)" containers supplied in nest & tub, or containers supplied in bulk.

- Easy and safe HEPA filters replacement from the front side. Standard filters.

- One single isolator construction shell which surrounds filling machine frame with a continuous jointless base.

- DPTE® solutions for product, closures, and tools transfer in & out of the isolator.

- Ideal for small scale clinical trials as well as for mass production.

- Cost-effective and optimized delivery time thanks to standard design and manufacturing.

Control system

- Single HMI for both filling line and isolator with integrated SCADA system.

- Integrated viable and non-viable particles monitoring system, and glove integrity tester.

- GAMP® 5 compliant software.

- 21 CFR part 11 compliant data acquisition system.

- Allen-Bradley or Siemens PLC.