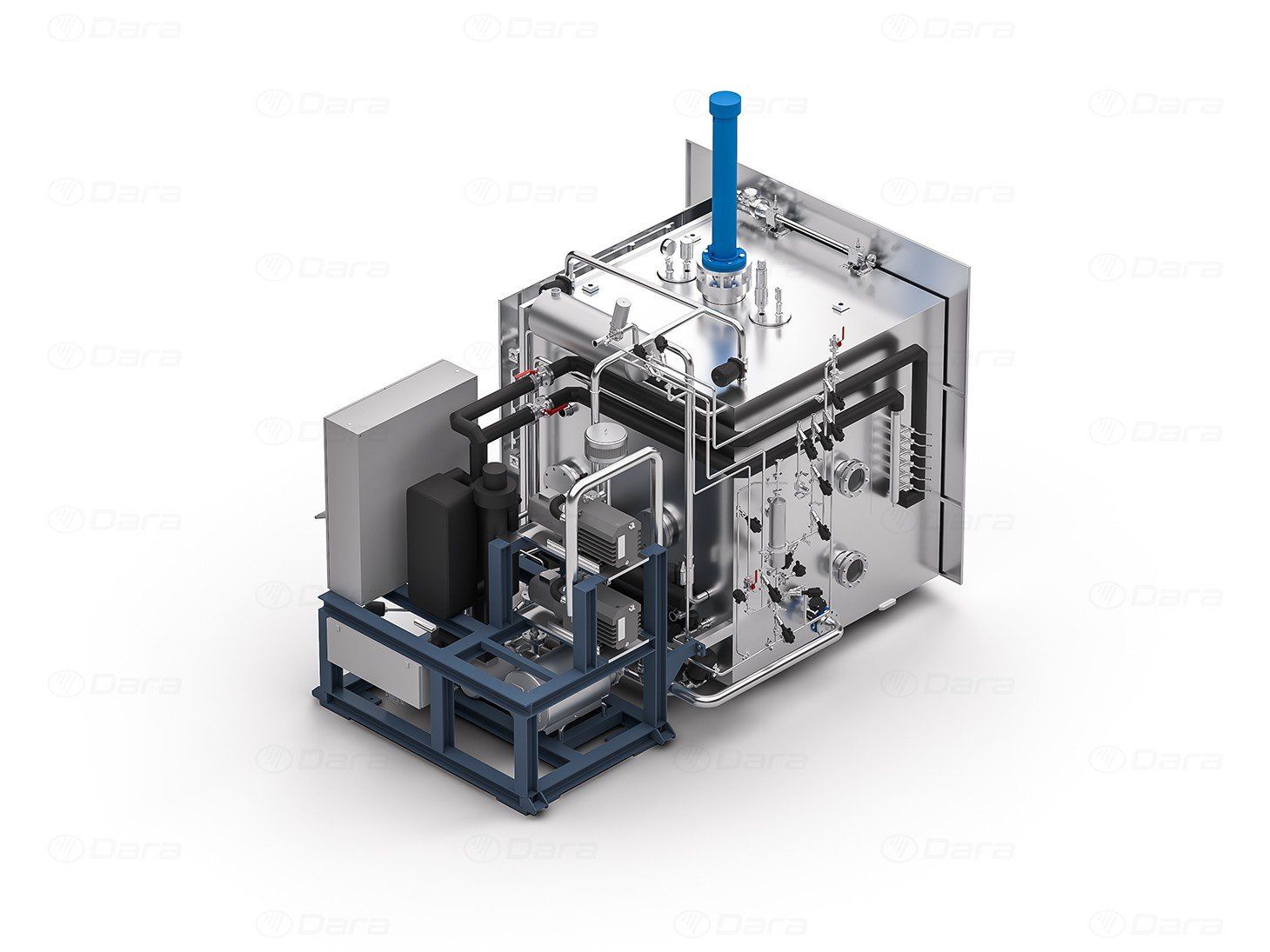

LyoCompact

Freeze Dryer

Compact solutions. Cutting-edge technology with a reduced footprint.

Main features

- Single body chamber and condenser.

- The bottom shelf as intermediate valve.

- Reduced plant footprint.

- Standalone frame for cooling system.

- Standalone frame for vacuum system.

- Chamber dimensions (W x H): 1,750 x 3,100 (≤3.6 m2) / 1,750 x 3,300 (≥4.32 m2) mm.

- Ice condenser temperature: -85˚C.

- Ice condenser capacity: 40 / 45 / 50 / 65 / 80 / 80 kg.

- Shelves temperature range: -60˚C to +85˚C.

Options

- The chamber: Rectangular chamber / Pressureless vessel / Injected foam insulation / Cooling by cold water circuit.

- Connection with condenser: Butterfly valve / Mushroom valve /Bottom shelf closing.

- Ice condenser: Integrated underneath, on the same floor / Integrated on the side, on the same floor / Outside, behind the camera, on the same floor / Outside, under the camera, on another floor.

- Shelves movement: Closing system hydraulic piston / Bellows / Connection with the automatic charging system.

- CIP: Chamber and condenser cleaning system / Recirculation system with heating / Multiple cleaning cycles.

- SIP: PED-EN13445 presssure vessel / ASME pressure vessel / Chamber cool-down after SIP.

- Plant distribution: 1st floor / 2 floors / Passthrough system.

- Additional elements: ATEX (processed with solvents and alcohol) / Cold tray loading / Frozen tray loading / Nucleation technology.

- Refrigeration: Piston compressor / Screw compressor / Liquid nitrogen system / Cascade system / Cooling system without PCA / Compressed air system.

- Door: Full size door / Automatic locking / Slot front door (constant loading level) / Full size sub-door / Cooling by cold water circuit.

- Process sensors: Pirani / Capacitive / Temperature probes (Pt-100 or Thermocouple) / Redundant temperature probes (Pt-100 or Thermocouple) / Wireless temperature monitoring / Full batch traceability software.

- Control systems: Rockwell or Siemens PLC / Integrated HMI / SCADA / Electronic recorder / Electronic Server and Think Client / Cycle optimization technology.

- Filter vent system: Sterilizable / Ports for integrity testing / Secondary venting cycle / Secondary vent filter / Water filter integrity test.

- Vacuum system: Sealed vacuum pumps with blowing system / Redundancy (additional pump) / Dry pumps with blowing system.